- Sales of optical measuring systems for static applications

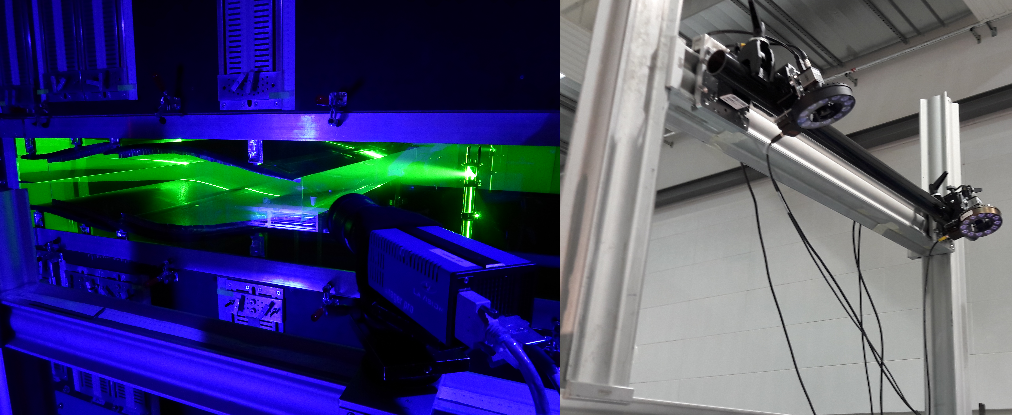

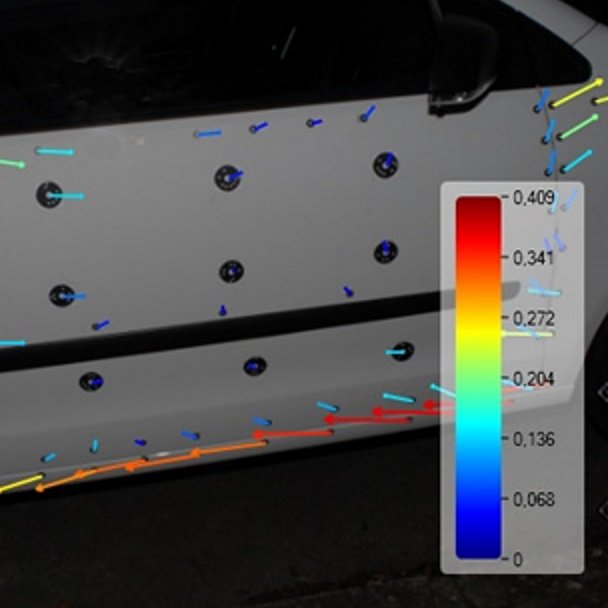

- Sales of optical measuring systems for dynamic applications

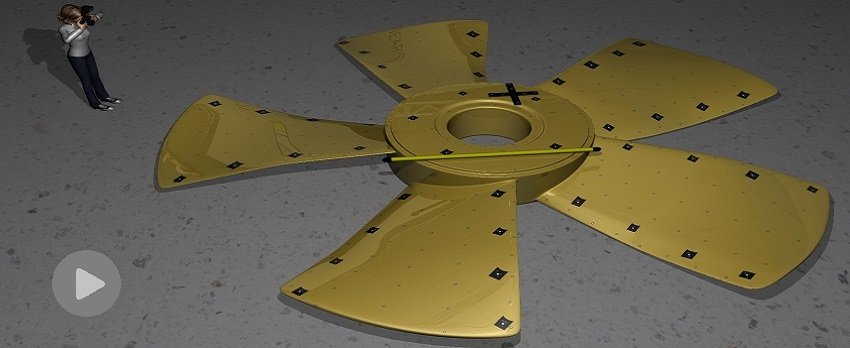

- Development of customized hardware and software solutions

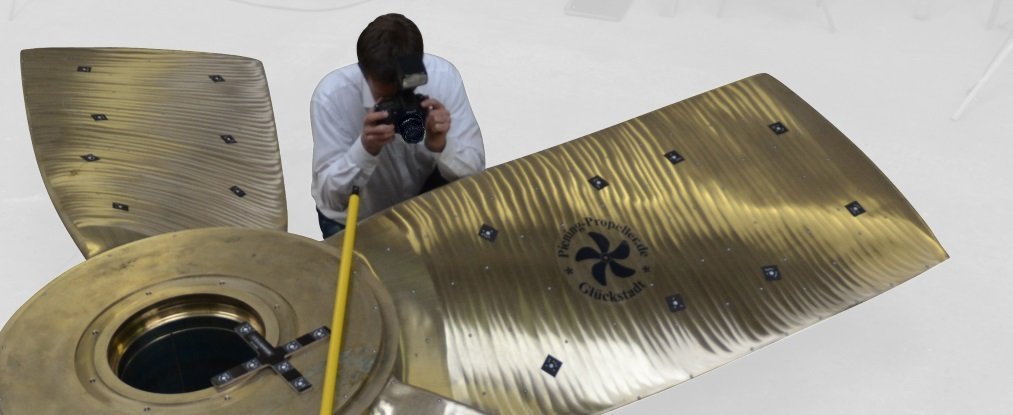

- Measurement services and evaluation of complex data

Quality assurance

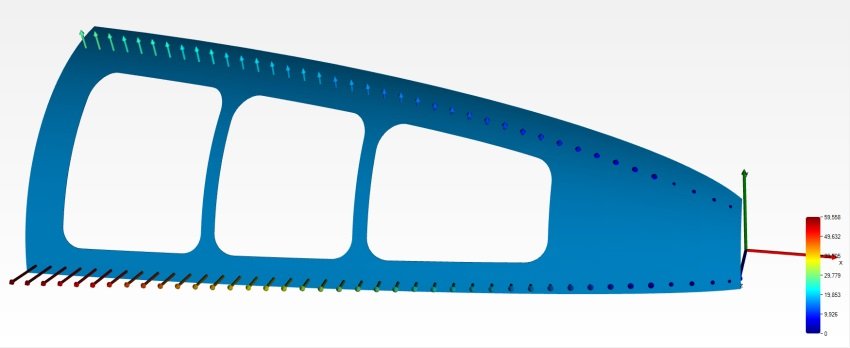

Deformation

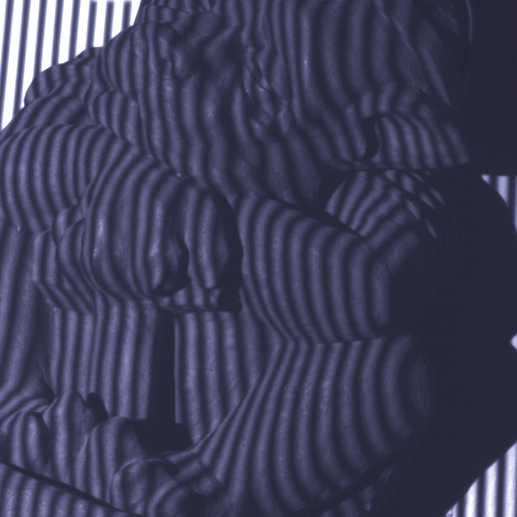

Scanning

Optical 3D coordinate measuring devices for static tasks

- Quality assurance for components up to 20m size

- Referencing of scanners

- Roundness and flatness testing

- CAD comparison and actual/nominal comparison

- Static deformation analysis

- Surveying applications for the craft

Dynamic Photogrammetry

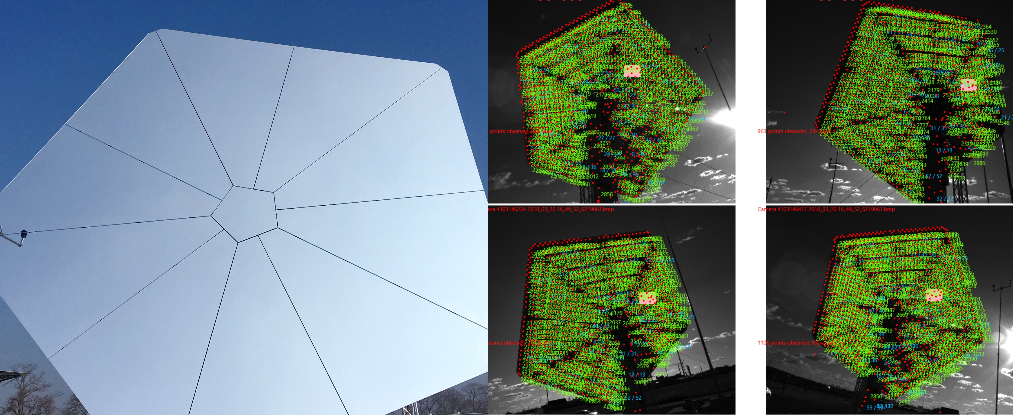

- Stereo: Dynamic deformation measurement for objects up to 10 m size

- Video: Measuring coordinates at high speed

Measuring services from orthophoto to deformation measurement

- Deformation measurements of objects under mechanical stress or climate change tests

- Data acquisition for reverse engineering

- Quality assurance