Fire Testing Deformation Measurement

PDF

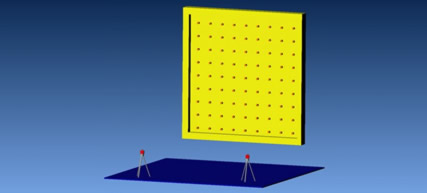

The system simplifies dynamic deformation measurements of large objects that range from two meters up to a

dozen meters in size. The object shown in Fig. 2 has a size of 6 x 6 meters. The marked measuring points are

displayed in orange.

It is perfectly suited for vertical fire testing applications due to its no-touch measurement, robustness

against smoke and precision. As a result it is a major benefit for work safety.

The system has been in constant use for years at several fire testing labs in Europe.

Features

- Two high-resolution DSLR or video cameras

- Resolution between 12 and 24 megapixels

- Measuring frequencies up to 0.1 Hz

- Free positioning of the cameras in front of the measuring object

- Unlimited measurement time

- Live-evaluation of results

- Accuracy in the order of a few tenths of millimeters

- Completely wireless configuration (WLAN, battery power) possible

- Fully automatable measurement process

Environment

- Standard room lighting is sufficient

- Smoke and dust do not affect the measurement

- Bumps and shocks during measurement are compensated

Measurement procedure

The cameras can be freely positioned in front of the target. Depending on the

application, either

a mobile calibration device or calibration markers may be used for camera orientation. The points to be

measured are identified

with self-adhesive markers.

System elements

- Two high-resolution digital cameras

- Notebook equipped with analysis software

- Markers

- Tripods

- Transport case

- WLAN transmitters (optional)