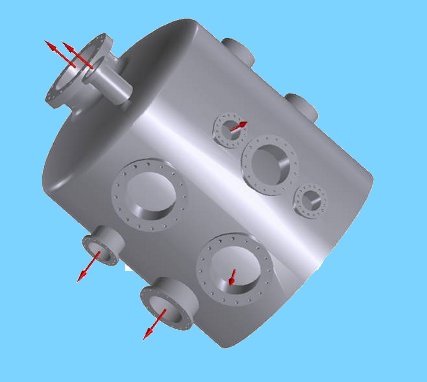

Chemical Reaction Tank

Task

In tank construction, it is important that the flanges are aligned as precisely as possible with the installation

environment. Tolerances of a few millimeters are hard to achieve for welded objects up to ten meters. An additional difficulty

are the complex spatial configurations of the flanges and other construction elements. Simple distance measurements are not

enough to guarantee the dimensional conformity of the container, e.g. for an as-built documentation for the end user.

Procedure

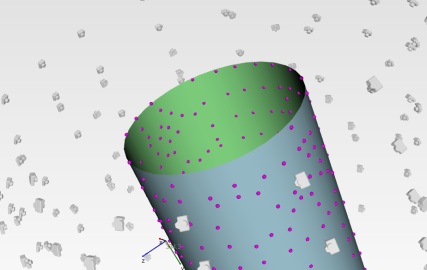

Approximately 400 targets are attached to the main cylinder which is then photographed from all directions.

The edges of the flanges are measured using adapters, giving the centers of the flanges. The flange centers are transformed

into the cylinder coordinate system. The first figure visualizes the measured normal vectors. The second figure shows the

measuring points on the cylinder and the camera positions.

Result

Photogrammetry yields fast and economic, high precision 3D information that conventional measuring methods do

not offer:

- Roundness of the cylinder

- Tilt of the cylinder relative to the base plate

- Angle of the flanges relative to each other

- Angle of the flanges relative to the normal on the calculated central axis of the cylinder

- Distance between the flange and the calculated cylinder surface

Advantages

- Measurement of geometric elements such as planes, cylinders, circles and straight lines

- "Difficult" dimensions can be checked according to the drawing (such as roundness, solid angle, parallelism)

- High accuracy