Photogrammetric measurement of a continuous caster

Task

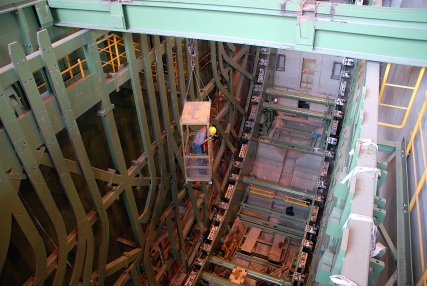

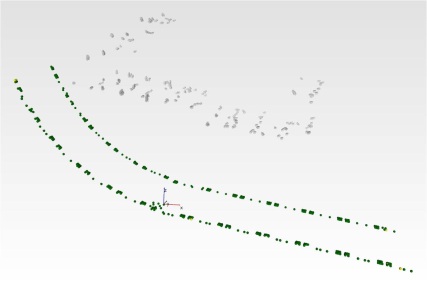

During the construction of a continuous caster at Salzgitter Stahl AG two measuring technologies were compared. The default technology was a laser tracker. Photogrammetry was evaluated as an alternative measuring approach.A continuous caster produces solid slabs from liquid steel. The liquid steel is shaped into a rectangular profile using a chill mold - a kind of cooled nozzle - as well as 14 support mills. Following a curved path the mills are arranged vertically at first, while the last mills are positioned horizontally.

The 14 mill segments are held by fixed and floating bearings. The fixed bearings were designed as pegs, the floating bearings as flat surfaces. The positions of these bearings were to be verified.

Measuring procedure

The photogrammetric measurement was divided in two steps. First, photogrammetry targets were attached to the bearings. The positions of the pegs relative to the photogrammetry targets were acquired using photogrammetric adapters. These measurements were done individually for the segments requiring a few dozen photographs each.The overall photogrammetric measurement was performed while hanging from a crane. Within 45 minutes almost 300 pictures were taken and the positions of all photogrammetric targets were acquired. Using the results from the preliminary measurement, the positions of the bearing pegs could be determined.